Ron's Woodshop

Ron has always enjoyed working with wood, but he started to get serious about his woodworking in 1998 when he was stationed at Kirtland Air Force Base in Albuquerque, New Mexico. He established his woodworking shop in Fayetteville, Tennessee in 2000 when he as reassigned to the Missile and Space Intelligence Center in Huntsville, Alabama. This page contains photographs of a few of his projects. He created the carved wood logo on the right with his new CNC machine and a single piece of rough sawn red oak he purchased at a lumber mill in Limestone County, Alabama several years ago. The wood had been drying for several years before he planed it down and cut it into a 12-inch square blank for the CNC machine.Water Regulator Storage Box

Cardboard Storage Box

CNC Machine

New Table Saw

Shop Improvements

With a new table saw in the shop, it was time for a few other improvements.

More Sewing Improvements for Debi

Wood Deck Project

Custom Frames

RV Improvements

End Tables

Letter Tray

Sewing Center

Thread Rack

Cutting Table

Cutting Table

This is one of my most complex projects. This cutting table for Debi's sewing room had to collapse down for storage, and I want the table height to be adjustable from 30 to 41 inches. The height adjustment is controlled by an automotive scissor jack, which limited the maximum height to 41 inches. I couldn't find a scissor jack with a 12-inch lift.

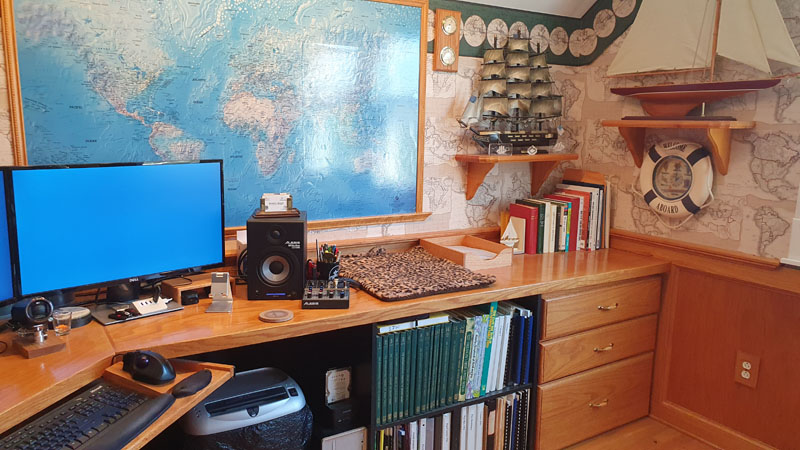

Studio and Office

Wooden Box

Woodshop Work Table

This is another table where the height is adjustable from 30 to 41 inches. The height adjustment is controlled by an automotive scissor jack, which limited the maximum height to 41 inches. I couldn't find a scissor jack with a 12-inch lift. This table did not have to collapse for storage, and it is designed to support very heavy projects.

Workbench

Copyright © 2025

Copyright © 2025